Polarization-Maintaining Fiber Coupler: Working Principle, Structure and Characteristics

🌟Introduction

Polarization-Maintaining Fiber Coupler (PM fiber coupler) is a special fiber device that can keep the polarization state unchanged during the transmission of optical signals. This device has important application value in modern optical fiber communication systems, optical fiber sensing, interferometry and quantum optics. This article will introduce the working principle, structural characteristics and performance characteristics of polarization-maintaining fiber coupler in detail.

🌟Working Principle of Polarization-Maintaining Fiber Coupler

1. Basic Working Principle

The core working principle of polarization-maintaining fiber coupler is based on the evanescent field coupling effect between optical fibers. When the cores of two polarization-maintaining optical fibers are close enough (usually within a few microns), the light field transmitted in one optical fiber will penetrate into the other optical fiber in the form of evanescent waves to achieve coupling and distribution of optical power.

Unlike ordinary single-mode fiber couplers, polarization-maintaining fiber couplers need to meet two conditions at the same time:

Achieve a specific optical power distribution ratio

Maintain the polarization state of the input light at the output end

2. Polarization maintenance mechanism

The key to the ability of polarization-maintaining fiber couplers to maintain polarization states is:

Matching principal axis alignment: The two coupled polarization-maintaining fibers must be precisely aligned with their fast and slow axes, usually in two configurations: “principal axis parallel” or “principal axis cross”

High birefringence maintenance: The coupling process cannot significantly reduce the original high birefringence characteristics of the fiber, ensuring that the polarization state is not randomly disturbed

Mode selective coupling: Only coupling between the same polarization modes (such as fast axis to fast axis, slow axis to slow axis) is allowed to occur, suppressing crosstalk between different polarization modes

3. Coupling efficiency and polarization extinction ratio

The performance of a polarization-maintaining coupler is mainly measured by two parameters:

Coupling efficiency: the ratio of the optical power at the output to the optical power at the input

Polarization extinction ratio (PER): a measure of the device’s ability to maintain polarization state, defined as the logarithmic value of the ratio of the power in the desired polarization state to the power in the orthogonal polarization state (in dB)

An ideal polarization-maintaining coupler should have a high polarization extinction ratio (usually >20 dB) and a precisely controllable coupling ratio.

🌟Structure of polarization-maintaining fiber coupler

1. Basic structural composition

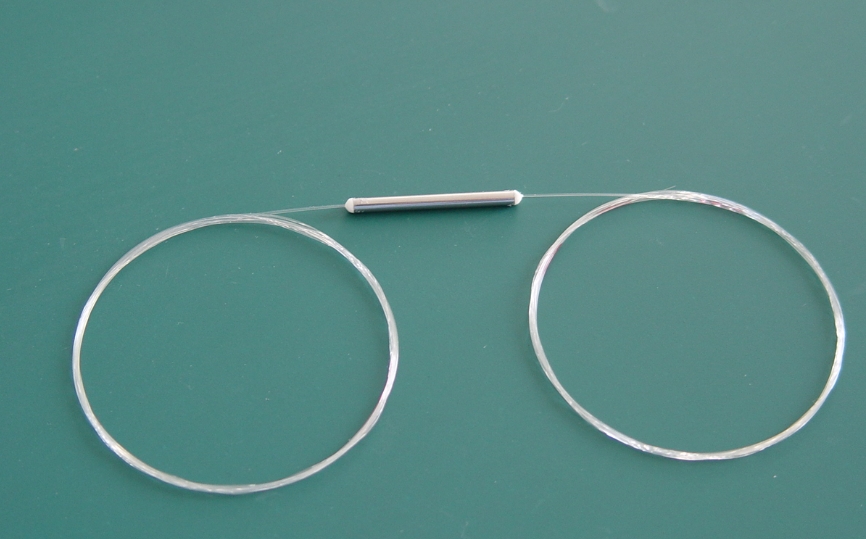

A typical polarization-maintaining fiber coupler consists of the following parts:

Input polarization-maintaining fiber: usually panda-type, bowtie-type or elliptical cladding polarization-maintaining fiber

Coupling region: the fused taper region of the two optical fibers, usually several millimeters in length

Output polarization-maintaining fiber: the structure is the same as the input fiber, maintaining polarization characteristics

Packaging protection: metal or ceramic shell, providing mechanical protection and temperature stability

2. Main structural types

(1) Fused taper type polarization-maintaining coupler

The most common structure, made by precisely controlling the fused taper process of two polarization-maintaining fibers. Key technologies include:

Precise axis alignment (error <1°)

Controllable taper speed and temperature

Optimized coupling region geometry

(2) Micro-optical polarization-maintaining coupler

Uses micro-optical elements (such as polarization beam splitting cubes, wave plates, etc.) to achieve polarization-selective coupling, with a more complex structure but more stable performance.

(3) Planar waveguide polarization-maintaining coupler

Integrated optical devices made of birefringent materials such as lithium niobate are suitable for mass production and miniaturized applications.

3. Main axis configuration method

Polarization-maintaining fiber couplers can be divided into the following types according to the relative directions of the fast and slow axes:

Parallel axis coupler: The fast axes (or slow axes) of the two optical fibers are parallel to each other

Cross axis coupler: The fast axis of one optical fiber is aligned with the slow axis of the other

Different configuration methods will affect the polarization characteristics and application scenarios of the coupler.

🌟Characteristics of polarization-maintaining fiber couplers

1. Performance characteristics

High polarization extinction ratio: The PER of high-quality polarization-maintaining couplers can reach more than 25dB

Wide wavelength operating range: Usually covers a wavelength window of tens of nanometers (such as 1550±20nm)

Low insertion loss: Typical value <0.5dB (depending on the coupling ratio)

Good temperature stability: PER degradation caused by temperature changes <0.1dB/℃

High power tolerance: Can withstand optical power from hundreds of mW to several W (depending on the design)

2. Technical advantages

Polarization state maintenance: Solve the polarization state randomization problem caused by ordinary couplers

System simplification: Avoid the use of additional polarization control elements

Interference stability: Especially suitable for Mach-Zehnder interferometer applications

Signal integrity: Maintain the fidelity of polarization modulated signals

3. Application characteristics

Fiber optic sensing system: used for polarization-sensitive applications such as distributed sensing and gyroscopes

Coherent communication system: maintain polarization state matching required for coherent reception

Quantum optics experiment: maintain entangled polarization state of photon pairs

Biomedical imaging: such as polarization-sensitive OCT system

Comments are closed